Shaker Screen Washer

On most rigs the shaker room is challenging in terms of working environment related to degassing of hazardous substances in the mud, noise and vibrations from shakers and other machinery in addition to ergonomic challenges.

Conventional screen washing solutions are usually cumbersome and time-consuming in use. Operators are often tempted to use manual high-pressure washers with the result that finely distributed hazardous substances are spread in the air. This entails the potential for serious health damage to the operators.

FDS has developed a completely new solution that provides fast and efficient washing of screens without harmful substances going astray.

The ergonomics associated with screen handling are significantly improved, and there will be significantly less spillage of mud in connection with the washing operation.

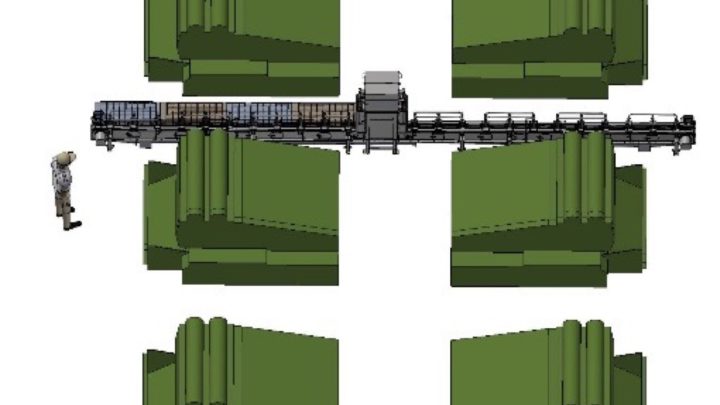

The solution is to place screens on the high edge, one after the other – on top of a narrow transport belt. Screens are then transported through a washing box equipped with high-pressure water nozzles so that both sides of the screens are washed at the same time. “Air knives” and air extractor prevent water mist /mud particles from escaping of the washing box. Cuttings / washing water flows down under the washing box and is drained to a suitable drain pot / cuttings duct.

Washing 4 screens takes about a minute, and screens are ready to be put back into the shaker / ready for inspection or repairs.

The machine must be specially laid out to fit the arrangement of the shaker room in question. We can perform survey and laser scanning to establish a 3D model of the shaker room with the washer placed in alternative places in the room.

Most HP washing facilities on drilling rigs will fall short in relation to the water requirement (about 100 bar, 100 l/min) during the washing sequence. We can supply high pressure pump units with ATEX classification or alternatively arrange for accumulator systems.